Effect of Temperature on Biogas Production: Insights for Biogas in Kerala

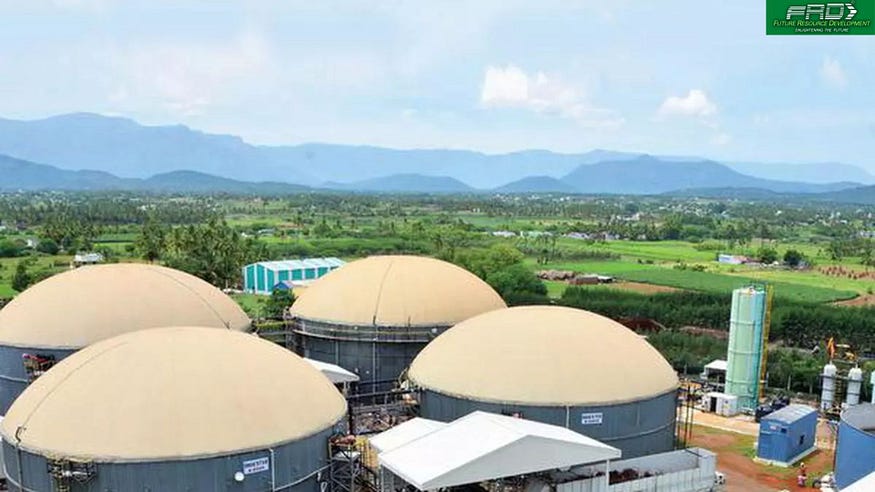

Biogas production is an eco-friendly solution for managing organic waste while generating renewable energy. In Kerala, where organic waste from households, agriculture, and industries is abundant, biogas plants play a crucial role in sustainable waste management. One of the most significant factors affecting biogas production efficiency is temperature. Understanding its impact can help optimize biogas generation and improve plant performance in Kerala’s climatic conditions.

Understanding the Role of Temperature in Biogas Production

Biogas is produced through the anaerobic digestion (AD) of organic matter by microorganisms. The efficiency of this process depends heavily on the operating temperature. The primary temperature ranges that influence biogas production are:

- Psychrophilic Range (Below 20°C):

- Microbial activity is significantly reduced.

- Biogas production slows down due to the low metabolic rates of bacteria.

- This range is not ideal for efficient biogas production.

- Mesophilic Range (25°C — 40°C):

- Most biogas plants, including those in Kerala, operate within this range.

- Mesophilic bacteria thrive, ensuring stable and continuous biogas production.

- Suitable for small-scale and household biogas units commonly found in Kerala.

- Thermophilic Range (50°C — 60°C):

- Higher metabolic activity leads to faster digestion and higher gas yields.

- Thermophilic bacteria require more careful management and control.

- Ideal for large-scale industrial biogas plants but requires additional heating.

Temperature Challenges for Biogas in Kerala

Kerala’s tropical climate generally maintains an ambient temperature between 25°C and 35°C, making it favorable for mesophilic biogas production. However, several challenges exist:

- Seasonal Variations: During monsoons, lower temperatures may slow microbial activity, slightly affecting gas yields.

- Excessive Heat: In summer, high temperatures can push biogas reactors towards thermophilic conditions, requiring proper monitoring to avoid microbial imbalance.

- Shading & Insulation Needs: Protecting biogas digesters from direct sunlight and using insulation techniques can help maintain an optimal temperature range.

Optimizing Biogas Production in Kerala’s Climate

To ensure steady biogas production in Kerala, the following strategies can be adopted:

- Use of Insulated Digesters: Prevents excessive heat loss during cooler months and stabilizes microbial activity.

- Temperature Control through Water Jackets: Helps regulate reactor temperature in extreme weather conditions.

- Pre-heating Feedstock: In colder months, slightly warming the input materials before feeding them into the digester can enhance microbial efficiency.

- Proper Reactor Placement: Positioning the biogas plant in a partially shaded area can help maintain a stable temperature.

Conclusion

Temperature plays a vital role in the efficiency of biogas in Kerala. While Kerala’s climate naturally supports mesophilic digestion, slight fluctuations in temperature can impact production. By adopting temperature regulation strategies, biogas plant operators can maximize output, ensuring a consistent and efficient source of renewable energy. As the demand for sustainable energy solutions grows, optimizing temperature conditions in biogas plants will contribute to Kerala’s green energy future.

Comments

Post a Comment